Custom Builds:

Food Truck/Trailer

Let’s start your custom food truck project together

Fill out the form below to request a quote for your next custom food tuck build.

Our Process

With our expert craftsmanship and unparalleled attention to detail, we specialize in creating bespoke food trucks that perfectly embody your unique vision.

We focus on benefits rather than features. Our expertly designed layout optimizes workflow, enabling you to create culinary masterpieces while maximizing productivity.

Let us transform your vision into a mobile culinary sensation. Seize this opportunity and revolutionize the way you deliver your delectable creations to the world. Your gourmet adventure awaits!

step 1

Conceptualization and Visualization

The first step is to work closely with you as our client to understand your vision, menu requirements, and operational needs.

It’s important to us that we fully meet your needs both creatively and visually. We’ll work close with you to brainstorm as well as guide you with our industry expertise to meld your vision with what would work best from an operational standpoint.

step 2

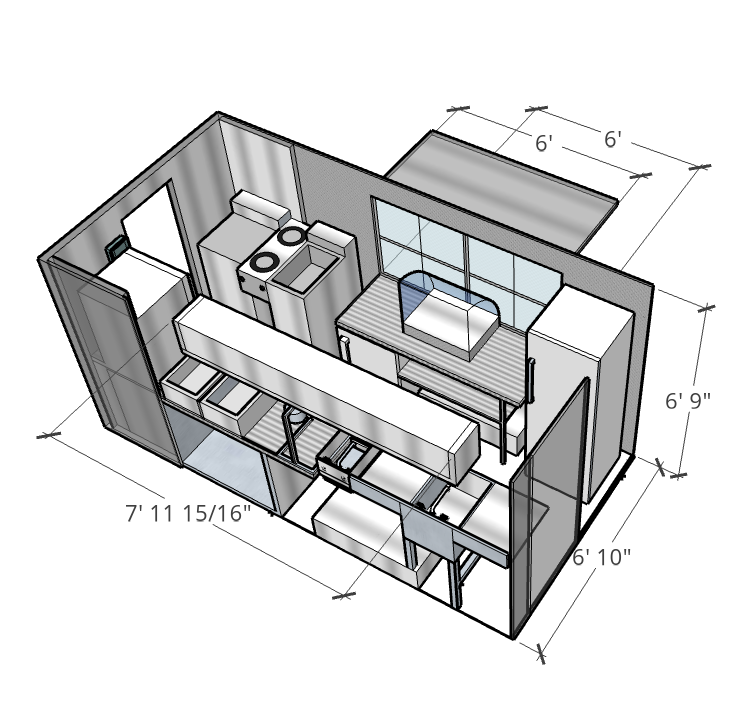

Design and Blueprinting

The next step in our process is to take everything that we brainstormed with you and build it out into a formal design.

We conceptualize your truck’s layout, consider equipment placement, storage areas, serving windows, and other custom features. Detailed designs and plans are created and presented to you for review and confirmation.

step 3

Fabrication and Customization

Once the design is approved, the fabrication process begins.

This involves customizing the food truck body, such as modifying the chassis, constructing the frame, and installing the necessary infrastructure for plumbing, electrical wiring, and ventilation. Flooring is installed, and walls are often covered with easy-to-clean materials.

Any requested visual features or additions, such as signage, graphics, or branding elements, are also incorporated during this stage.

step 4

Interior Finishing

The Interior of the unit is finished with the materials specified by the client. Options include, but are not limited to, aluminum, FRP, and stainless steel. Ceiling coverings are also installed if necessary, as well as shelving, and food prep surfaces. This step also will include any other custom elements not yet addressed.

step 5

Equipment Installation

The next step is to install the kitchen equipment and appliances as per the your requests and menu requirements. This includes installing commercial-grade cooking equipment (such as grills, fryers, ovens), refrigeration units, sinks, water tanks, and other necessary fixtures.

Special attention is made and special care is taken to ensure proper positioning for efficient workflow and compliance with safety regulations.

step 6

Testing and Quality Control

Before delivery, thorough testing is conducted to ensure that all systems, equipment, and utilities are working properly. Quality control checks are performed to ensure the food truck meets the agreed specifications, design standards, and functionality.

step 7

Hand-Off and Training

Once the food truck is complete, it is delivered to the client. At this stage, the client may receive training on how to operate and maintain the food truck, including instructions on using equipment, cleaning protocols, and routine maintenance procedures.